If you think a heat exchanger sounds like some interdimensional portal that lets out hot air, then you’re partially right.

However, the reality is that it’s a device used to transfer thermal energy (or heat) between two fluid systems.

In this blog post, we’ll explore everything there is to know about these fantastic pieces of machinery – from their purpose to how they work.

What is a Heat Exchanger in The Furnace?

A heat exchanger in a furnace is an important component in transferring thermal energy from the burning fuel to the air or other gases passing through it.

This heat exchanger typically comprises a metal chamber where the fuel is burned and either a series of tubes or plates that run through the room containing air or gas.

As the fuel burns, the heat is absorbed by the metal walls and then transferred to the air or gas passing through it.

This process helps to maintain an efficient and safe operating temperature in a furnace. Heat exchangers are used in many furnaces, including gas and oil furnaces, wood stoves, pellet stoves, and more.

Types of Heat Exchangers in The Furnace?

Several types of heat exchangers are used in furnaces, each with different advantages and disadvantages.

The most common types of heat exchangers are shell and tube, plate, Double Tube Heat Exchangers, and Tube in Tube Heat Exchangers.

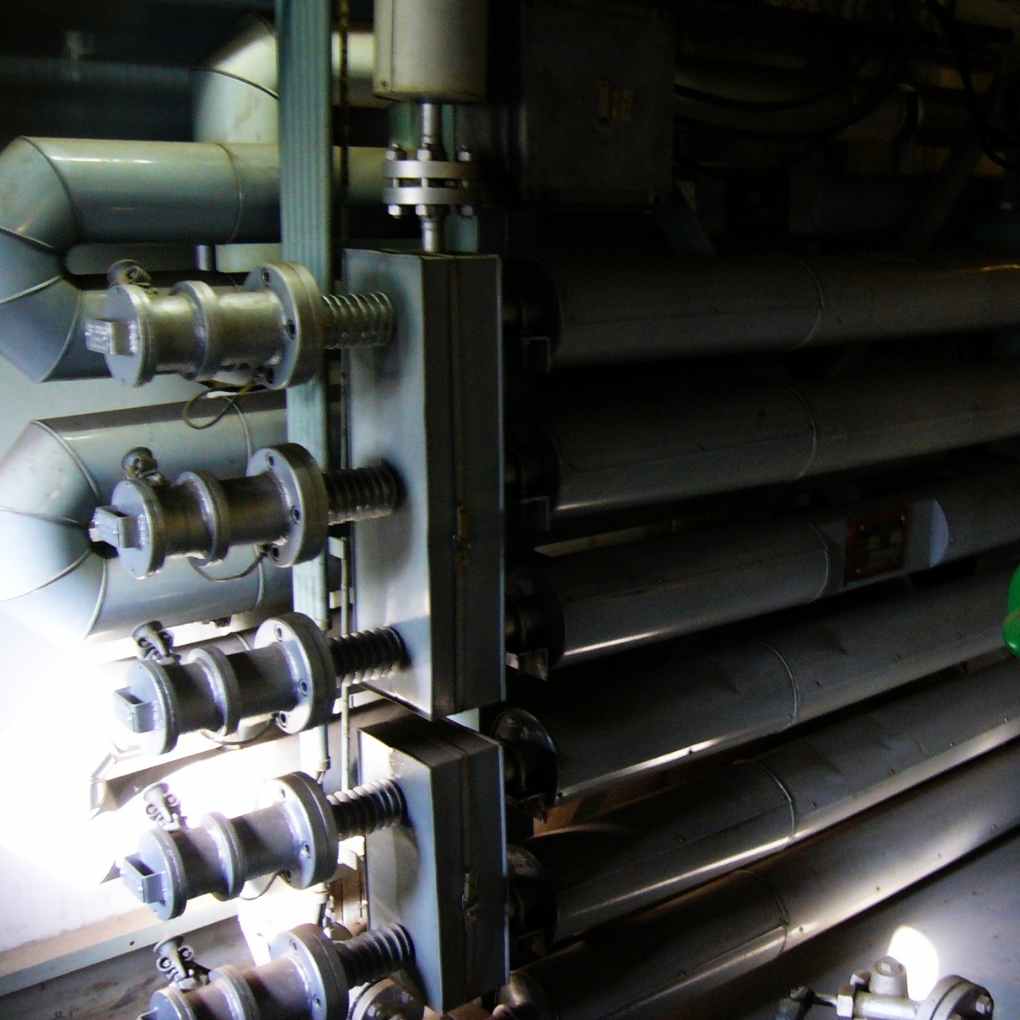

Shell and Tube Heat Exchanger

Shell and Tube Heat Exchangers are a modern technological marvel, revolutionizing the way people exchange heat.

These efficient devices, made up of a bundle of tubes inside a larger cylindrical vessel, can be custom-designed for both typical applications and more sophisticated uses.

They allow heat to be exchanged through metal walls while keeping the two substances completely separate.

And because they require very little maintenance, these exchangers can be found in nearly every industry, from oil refining to air conditioning.

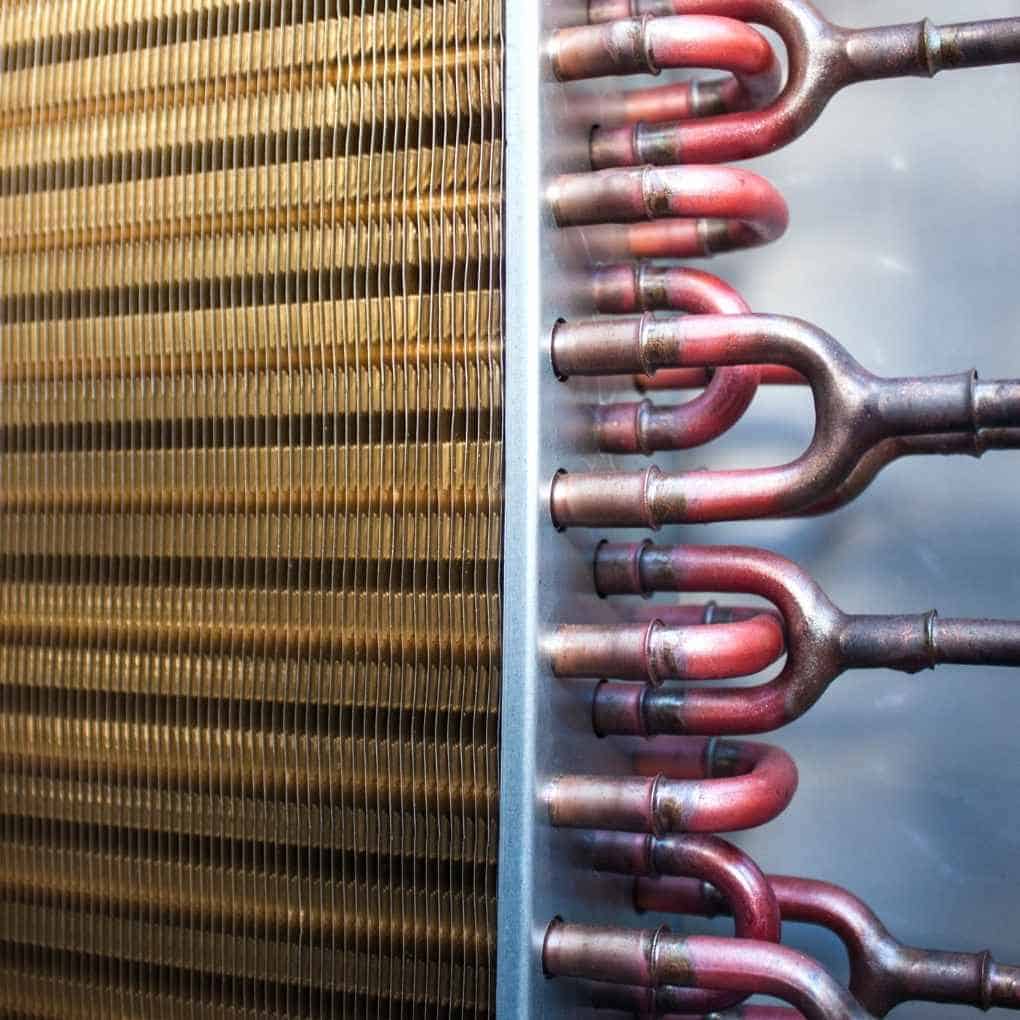

Plate Heat Exchanger

Plate-and-fin heat exchangers are designed to transfer heat more efficiently than shell-and-tube designs.

Commonly used in refrigeration and cooling systems, plate heat exchangers use a series of stainless steel plates to transfer thermal energy between two liquids — without mixing them.

Not only are plate heat exchangers excellent for their efficiency, but they are great for maintenance too, with easy access points for cleaning and servicing where needed.

A plate heat exchanger is the most effective compared to other heat exchangers but a plate heat exchanger is more expensive than others.

Double Tube Heat Exchangers

Double-tube heat exchangers utilizing two tubes can efficiently take the heat from one side and transfer it to another more quickly than single-tube exchangers.

Also Read: Is a Buzzing Furnace Dangerous?

They can also be designed for restricted spaces, as their smaller diameter allows them to fit into tighter quarters while still allowing adequate flow rates.

They are quite versatile and able to handle high temperatures and pressures, as well as any fluid or gas imaginable.

Tube in Tube Heat Exchangers

Tube-in-tube heat exchangers has been widely used for decades due to their reliable performance and high efficiency.

These exchangers operate by transferring thermal energy from a primary steam system to a secondary clean process stream by flowing the process medium through inner tubes and the heat transfer media along the outer shell.

It works much like an insulated thermos bottle; the two fluids never come into contact with each other, maximizing both safety and productivity without sacrificing any performance.

Applications of Heat Exchangers in a Furnace

Heat exchangers play an important role in furnaces, as they are integral components of many efficient heating systems.

Heat exchangers transfer thermal energy from the burning fuel to the air or other gases. This allows for an efficient and safe operation while reducing emissions and providing a clean fuel burn.

Find out more about Air Quality, Air Cooling, and Heating at Homezephyr.com

Working Principles of Heat Exchangers in a Furnace

The working principle of a heat exchanger in a furnace is based on the transfer of thermal energy from the burning fuel to the air or other gases passing through it.

This is done by using a series of tubes and plates that form a metal chamber where the fuel is burned, which allows heat to be absorbed and transferred to the air or gas passing through it.

Heat exchangers are designed to maximize the efficiency of the heat transfer process so that the fuel burns cleanly and efficiently.

[elementor-template id=”2495″]

Safety Measures for Heat Exchangers in a Furnace

It is essential to take certain safety measures when installing and maintaining heat exchangers in a furnace, as these components can become extremely hot during operation.

Before installation, make sure to read the user manual and follow all of the instructions carefully.

Additionally, heat exchangers should be inspected regularly for signs of damage or wear and serviced periodically by a qualified technician to ensure efficient operation.

Finally, combustible materials should always be kept away from any heat exchanger to avoid the risk of fire or explosion.